TENDER FILE

Strengthening Our Brand Value by Creating Innovation Capacity with Vacuum Heat Treatment Service and Creating Additional Employment Project Tender

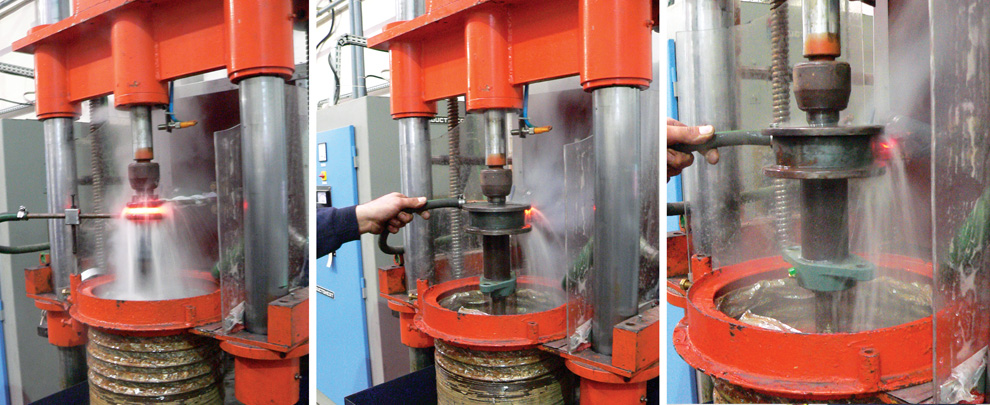

The heating speed and the heating area can be controlled very easily. This is particularly advantageous in sensitive induction hardening and prevents unnecessary heating of the other parts of the steel. Therefore, no deformation occurs on the untreated part of the material due to unnecessary heating.

Hardness values of 60 - 62 HRC (depending on steel type) can be reached on the surface. The hardness range can be adjusted from 2 to 7 mm depending on the area of the steel use. Length: 3000 mm and Diameter: Up to 4000 mm can be hardened by induction heating.

The shorter heating time reduces the possibility of distortion, cracking and grain coarsening. The method can be easily and precisely controlled. Only the desired parts of the steel can be hardened and the other parts remain ductile. Unlike other annealing methods, a non-porous structure is obtained due to the non-scale being on the surface. Error rate is minimized with 100 % computer controlled induction hardening.

Pin, Bolt, Shaft Hardening Gear Types Reel and Bandage Wheels (Diameter: 4000mm) Blade Hardening Plastic Extrusion Barrel and Bushing Hardening

Strengthening Our Brand Value by Creating Innovation Capacity with Vacuum Heat Treatment Service and Creating Additional Employment Project Tender