TENDER FILE

Strengthening Our Brand Value by Creating Innovation Capacity with Vacuum Heat Treatment Service and Creating Additional Employment Project Tender

Astaş Heat Treatment was established in 1989 by Rıfkı BAYRAM and Hasan AYAZSEVEN as the first professional heat treatment plant of Çukurova region in order to solve the heat treatment problems by knowing the problems and needs of the machinery-manufacturing industry in the region.

We can proudly say that the reliance on ASTAŞ Heat Treatment has played a big role for the development of the machinery supply industry in the region. The only reason for reaching an annual heat treatment capacity of 3500 tons is the unwavering trust of its customers to Astas Heat Treatment. Astas Heat Treatment Management fulfills its responsibilities completely in order to be worthy of this trust.

TS EN ISO 9001: 2015 TS EN ISO 9001: 2015 quality management system is applied in ASTAŞ Heat Treatment Plant. Our Heat treatment furnaces are computer controlled and process and control results are continuously recorded.

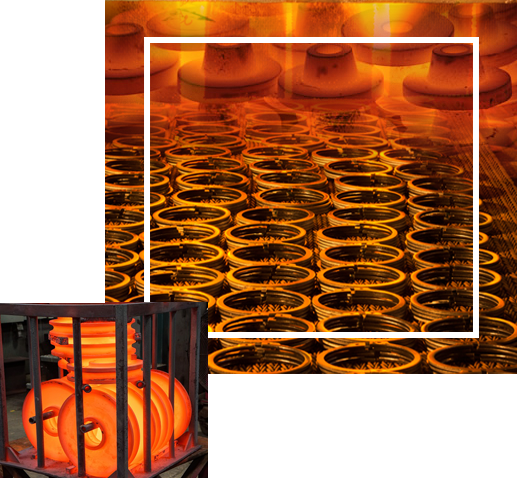

Atmosphere Controlled Furnaces Induction Surface Hardening Vacuum Furnace Softening Annealing Stress Relief Annealing Normalising Recrystallisation Carburizing Hardening Process Quenching Tempering Age Hardening Aluminium Laboratory

We can proudly say that the reliance on ASTAŞ Heat Treatment has played a big role for the development of the machinery supply industry in the region. The only reason for reaching an annual heat treatment capacity of 3500 tons is the unwavering trust of its customers to Astas Heat Treatment. Astas Heat Treatment Management fulfills its responsibilities completely in order to be worthy of this trust.

Strengthening Our Brand Value by Creating Innovation Capacity with Vacuum Heat Treatment Service and Creating Additional Employment Project Tender

The heating speed and the heating area can be controlled very easily. This is particularly advantageous in sensitive induction hardening and prevents unnecessary heating of the other parts of the steel. Therefore, no deformation occurs on the untreated part of the material due to unnecessary heating.